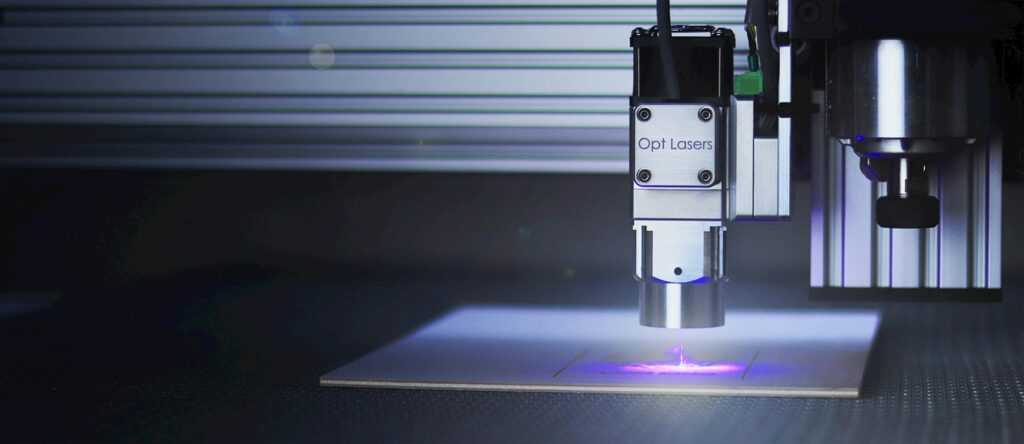

Laser technology has transformed the manufacturing industry, delivering unmatched precision, efficiency, and versatility. As a cornerstone of the economy, manufacturing has embraced laser cutting as an indispensable tool. This post delves into the impact of laser cutting in Utah, examining how it is reshaping the local manufacturing landscape and its broader significance for the industry as a whole.

Enhanced Precision and Efficiency

Laser cutting technology offers precision that far surpasses traditional mechanical methods. Its capability to create intricate designs and detailed patterns with exceptional accuracy has revolutionized manufacturing, unlocking new possibilities for innovation.

Benefits of Precision Laser Cutting

Laser cutting enables manufacturers to create intricate parts with exceptional precision and tighter tolerances, minimizing the need for additional finishing steps and accelerating production timelines. This level of efficiency is vital in industries where accuracy is non-negotiable, such as aerospace, electronics, and medical devices.

Cost Reduction and Material Savings

A key advantage of laser cutting is its exceptional efficiency in reducing waste. Its precise technology ensures optimal material usage, resulting in significant cost savings.

Streamlining Production

Laser cutting simplifies production by minimizing the steps needed to create a part. This approach not only speeds up the process but also lowers labor costs and reduces material waste, contributing to more efficient and sustainable manufacturing.

Versatility Across Materials

Laser technology is incredibly versatile, capable of cutting through a wide range of materials, including steel, aluminum, wood, plastic, and more. Its adaptability makes it an invaluable tool across numerous industries.

Expanding Manufacturing Capabilities

Laser cutting’s versatility enables manufacturers to diversify their product lines and respond swiftly to market shifts or customer needs, all without the need for substantial investments in new equipment.

Customization and Rapid Prototyping

Laser cutting supports customization and rapid prototyping, enabling manufacturers to produce small batches of customized products efficiently or prototypes that can be quickly revised based on real-world testing and feedback.

Enhancing Innovation

This capability drives innovation by allowing companies to experiment with designs without the burden of high costs or lengthy delays. In dynamic markets, it enables quicker innovation cycles, helping businesses remain competitive in fast-moving industries.

Automation and Integration

Modern laser cutting machines are often part of automated production lines, integrated with computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. This integration allows for seamless production workflows from design to finished product.

Improving Workflow Efficiency

Automation minimizes human error while significantly boosting production speed. In the manufacturing sector, where efficiency and speed are essential for profitability, the adoption of laser technology has revolutionized the industry.

Safety and Environmental Impact

Laser cutting offers a more efficient, cleaner, and safer alternative to traditional manufacturing methods. By generating fewer particulates and minimizing noise and vibration, it helps create a healthier, safer workplace environment.

Promoting Sustainability

The precision and efficiency of laser cutting minimize waste, making it a more sustainable choice for manufacturing. As industries increasingly prioritize eco-friendly production methods, laser cutting plays a vital role in supporting greener practices.

Conclusion

Laser technology has profoundly transformed modern manufacturing, redefining how industries operate and produce goods. Its advantages are vast, offering unparalleled precision, cost efficiency, material versatility, and enhanced safety standards. With laser cutting, manufacturers can create intricate designs with exceptional accuracy, minimizing waste and optimizing production processes. This technology’s ability to work seamlessly with diverse materials—ranging from metals and plastics to wood and ceramics—underscores its versatility across countless industries.

Far from being just a technological upgrade, laser cutting has become a cornerstone for innovation and competitiveness in manufacturing. By streamlining operations and enabling groundbreaking product designs, it has set a new benchmark for efficiency and quality. As laser technology evolves, its transformative potential continues to grow, ensuring that forward-thinking manufacturers who embrace these advancements remain leaders in their fields. In an increasingly competitive market, adopting laser technology isn’t just an advantage—it’s a necessity for future success.